On Machine Verification System

On Machine Verification System

OMV stands for On Machine Verification. It's a system that combines a spindle probe and software to create NC programs for machining centers from 3D models. Additionally, it collects feedback from the machine after probing and provides an Excel report of the part dimensions.

-

OMV before machining

- • Work Origin Determination:

- Probes reference points on the workpiece or fixture. Establishes precise work origin for all machine axes.

- • Part Seating Verification:

- Ensures proper alignment and seating of the part on the fixture.Reduces errors caused by misalignment or improper fixturing.

- • Part Identification:

- Confirms the correct part is loaded onto the machine.Minimizes the risk of production errors by using the right program and tooling for each part.

-

OMV after machining

- • Utilizes 3D model data to generate NC programs for inspection purposes.

- • Dimension Measurement:

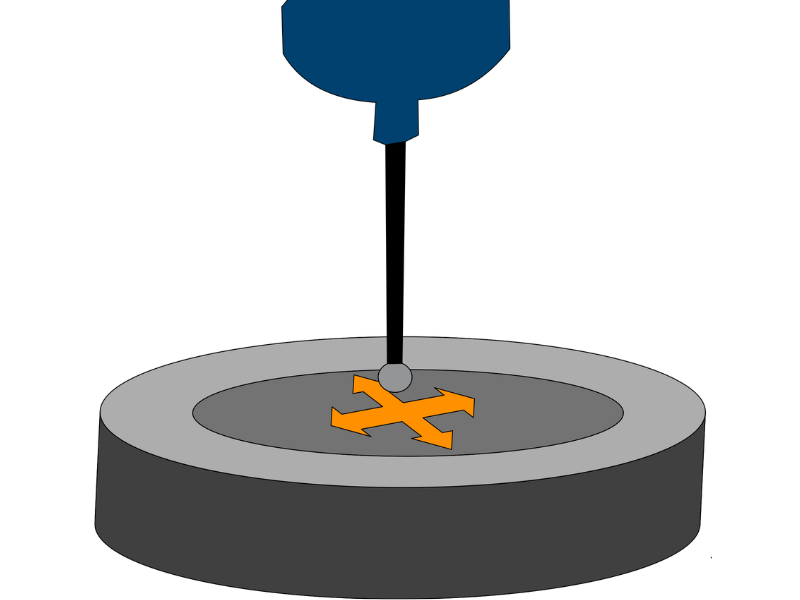

- • Bore diameter

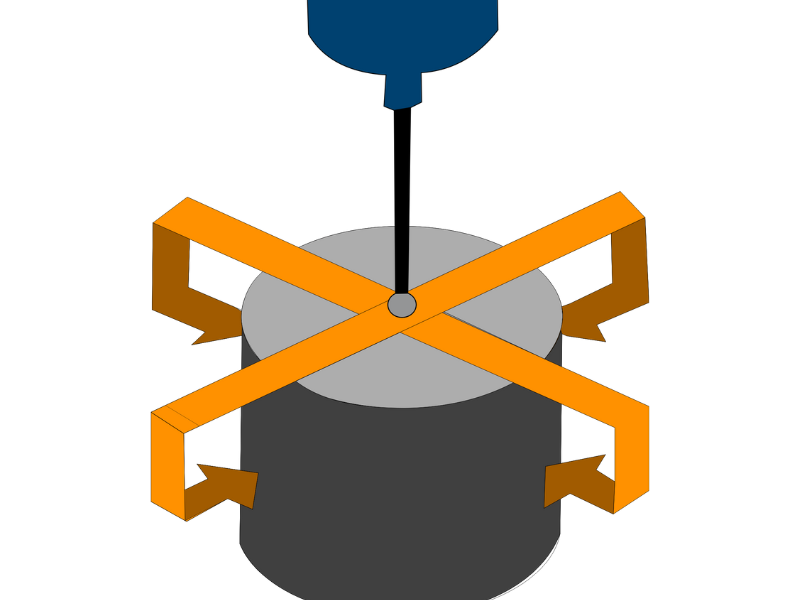

• Boss dimensions

• Pitch Circle Diameter (PCD)

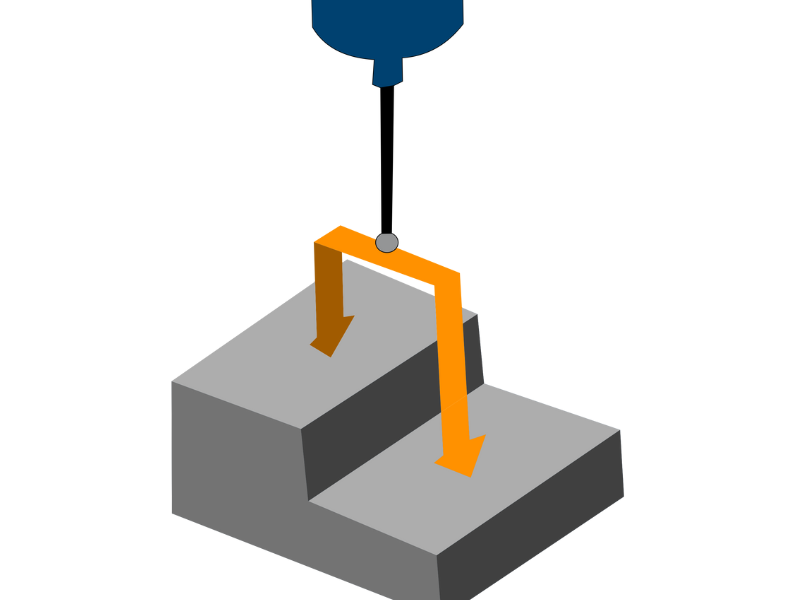

• Plane dimensions

• Angles

• Depth

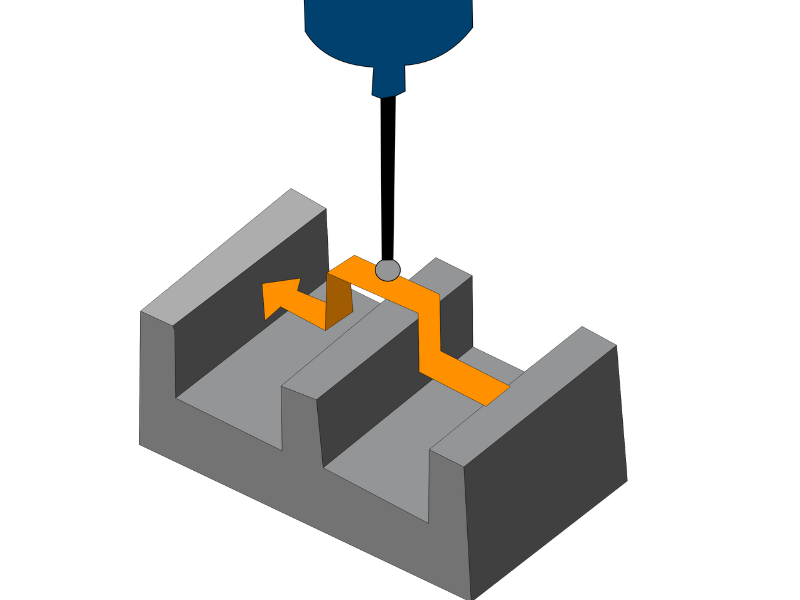

• Width

• Gap measurements

And more, depending on the specific requirements.

• Measures various dimensions such as:

-

Gallery